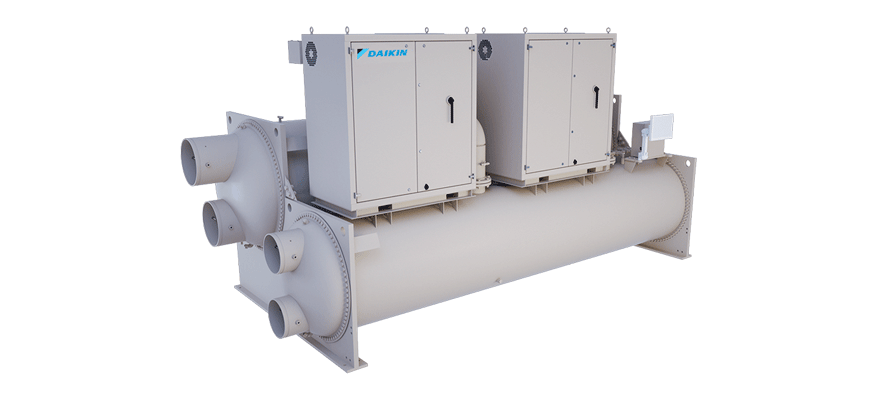

A chiller is a piece of HVAC hardware used to make things cool. While there is an assortment of chillers, including air-cooled chillers, the term is ordinarily used to allude to a gadget that chills liquids, like water. That kind of gadget is developed with a blower, condenser, an evaporator and a warm extension valve. Chillers are an important instrument for some, positions, including cooling a structure alongside various mechanical applications. The cycle a chillers executes to cool a fluid starts with the gadget’s blower. The chillers’ blower siphons refrigerant inside, what begins the cooling cycle as a hot packed gas. This refrigerant is siphoned to the condenser, which starts to consolidate the gas into fluid as it gets cooled by a fan. During this progression all the while, a large part of the warmth is smothered of the chillers.

When the gas has gone through the condenser and has gotten a cooled fluid, it continues onward to the warm development valve. From here the measure of refrigerant that enters the evaporator can be controlled. At the point when refrigerant advances into the evaporator, it assimilates warmth and afterward bubbles off, which makes it is anything but a fume. Then, at that point water is sent through the evaporator that is warmed by the refrigerant. From here, the refrigerant enters the blower once more, is transformed into that underlying hot packed gas referenced before and is sucked into the condenser. This leads back to the start of the cycle.

Chillers are available in cooling frameworks. Their job is that of a chilled water framework during the way toward cooling the air. This interaction is recurrent. An air-cooled chiller utilized for a cooling framework can be somewhere in the range of 15 to 1,500 tons and cools water to a temperature of 35 to 45 degrees Fahrenheit. Chillers have numerous mechanical applications too. They can be utilized to chill heat squander put by an assembling interaction that is then used to cool the air. Chillers are expected to cool warmth squander delivered by focused energy lasers.

They can likewise be utilized to cool work pieces being sliced by machine apparatuses or to appropriately control the temperature of MRI hardware. Since chillers have a wide scope of utilizations, while picking one for your mechanical application there are a few things to mull over. These incorporate what sort of material was utilized during development, which segments were utilized, its energy proficiency, convenience, how simple it will be to perform upkeep work on the gadget and the subtleties of its guarantee.